Introduction

Solar energy is abundant, non-pollutant, and renewable form of energy. It can be effectively used for product drying, if harvested properly. The traditional technique for product dehydration is the open sun drying method which has many disadvantages like product pollution and contamination. An advanced and alternative method to the traditional techniques is greenhouse drying. In greenhouse drying the product is placed in trays which receive solar radiation through the plastic cover and moisture is removed either by natural convection or forced air flow. The use of appropriate greenhouse dryer improves the quality of the product and lead to reduction of drying time interval (Condori et al., 2001).

Khoa is a heat desiccated, partially dehydrated milk product. It forms an important base for preparation of milk sweets which are an integral part of the Indian food heritage. About six lakh tonnes of khoa is being manufactured annually, mostly in private and unorganized sectors of India by utilizing about 7% of the total milk produced (Kumar et al., 2010; Kumar 2013). It contains sufficient amount of moisture which helps in the growth of microorganisms. The shelf-life of khoa is chiefly influenced by the moisture contents among other factors like storage temperature, raw material quality, sanitation conditions, and packaging. The presence of moulds in khoa causes its fast deterioration by producing discoloration defects as well as disagreeable flavors. Solar radiation significantly reduces the counts of these microorganisms (Kumar et al., 1996; Chavan, and Kulkarni, 2006; Rajarajan et al., 2007).

Khoa drying is a continuous heat and mass transfer phenomenon. The heat energy supplied to the khoa surface is utilized in two ways, i.e., to remove the moisture present in the product through the provision of latent heat of vaporization and to increase the product surface temperature in the form of sensible heat which causes evaporation of the moisture to the surrounding air. Removal of moisture occurs from the interior of the khoa due to induced vapor pressure difference between the khoa and the surrounding medium. The convective heat transfer coefficient is an important parameter in drying rate simulation, since the temperature difference between the air and the product varies with this coefficient. The convective mass transfer coefficients for various shapes and sizes of jaggery pieces in a controlled environment were evaluated by Tiwari et al., (2004). It was observed that the convective mass transfer coefficient in forced convection is higher than the natural convection mode. The effect of shape and size of jaggery for a given mass on convective mass transfer coefficient for natural as well as forced convection greenhouse drying was studied Kumar and Tiwari (2006). The convective heat transfer coefficients of khoa were investigated by Kumar et al. (2011a) in an open sun drying and greenhouse drying for natural as well as for forced convection modes for drying a khoa piece of size 0.09 × 0.06 × 0.015 m3 for three consecutive days. The convective heat transfer coefficients under forced convection were reported higher than the natural convection mode. The convective heat transfer coefficients were observed to decrease with the drying day progression from the first day to the third day and were found to vary in a range of 0.54 to 1.09 W/m2 oC.

In the present study the effect of size on the convective heat and mass transfer coefficients of khoa for a given mass with greenhouse drying under natural convection mode has been evaluated. This research work would be helpful in the design of an efficient greenhouse for drying khoa to its optimum storage moisture level.

Materials and Methods

Experimental Set-Up and Instrumentation Details

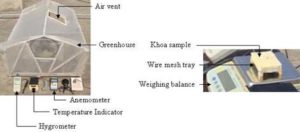

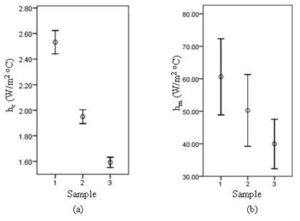

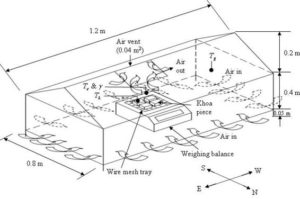

A roof type even span greenhouse of 1.2 × 0.8 m2 effective floor area was fabricated of PVC pipe and a UV film covering of 200 microns. The central height and the walls were maintained as 0.6 m and 0.4 m respectively. An air vent with an effective opening of 0.043 m2 was provided at the roof for natural convection. A photograph of the experimental setup for greenhouse drying and khoa sample is shown in Fig.1

Fig. 1: A Photographs of Experimental Unit

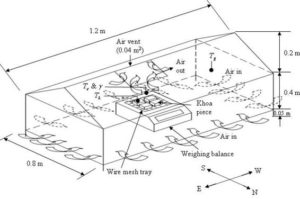

Experimental unit was located on the open floor of a three-floor building to have a good exposure to the solar radiation. Due to more availability of sunlight the orientation of the greenhouse was kept east-west. The experiments were carried out with total quantity of khoa as 100 g for each dimension of the khoa pieces, i.e., 0.025 × 0.02 × 0.015 m3, 0.0375 × 0.03 × 0.015 m3, and 0.075 × 0.06 × 0.015 m3. For each experiment, khoa pieces of 1.5 cm thickness for single layer drying were kept in a wire mesh tray of 0.09 m × 0.06 m size directly over the digital weighing balance of 6 kg capacity (TJ-6000, Scaletech, made in India) with a least count of 0.1 g. The khoa and air temperatures at different locations were measured by calibrated copper-constantan thermocouples connected to a ten channel digital temperature indicator with a least count of 0.1 oC. For measuring khoa surface temperature four thermocouples were placed at the sample surfaces and then their average value was considered. To obtain accurate readings of the temperatures the thermocouples have been calibrated with respect to the ZEAL thermometer (made in England). The relative humidity (γ or RH) and the temperature just above the khoa surface was measured by a digital humidity/temperature meter (Lutron-HT 3006, made in Taiwan) with least counts of 0.1% RH and 0.1 oC. The various dimensions and the locations of measured parameters are shown in a schematic of the experimental unit in Fig. 2.

Fig. 2: A Schematic View of Experimental Unit

Sample Preparation and Experimental Observations

The khoa sample was prepared by following the traditional khoa making process. The fresh milk was heated over an electric hot plate in an aluminum open pan. The heating was stopped and the product was allowed to cool to room temperature when the desired consistency was obtained. Then cuboids shaped pieces of khoa sample of size 0.025 × 0.02 × 0.015 m3, 0.0375 × 0.03 × 0.015 m3, and 0.075 × 0.06 × 0.015 m3 of total quantity of khoa as 100 g were prepared with the help of wooden molds. For each experiment performed fresh sample of khoa of the same shape and mass was prepared by following the above procedure. The observation time interval for khoa drying was taken an hour. Experiments were performed during the month of October 2012 at Guru Jambheshwar University of Science and Technology Hisar (29o5’5” N 75o45’55” E).

Procedure

For each experiment the initial mass of khoa samples was kept constant as 100 g. The khoa sample was kept in the wire mesh tray directly over the digital weighing balance. The moisture evaporated was calculated by taking the difference of mass of khoa between two consecutive readings. The hourly data for rate of moisture removal, khoa surface temperature, relative humidity inside the greenhouse, temperature just above the khoa surface, and ambient temperature have been recorded. The khoa samples were dried till no variation in its mass was recorded.

Theoretical Considerations

Thermal Modeling and Computation Technique

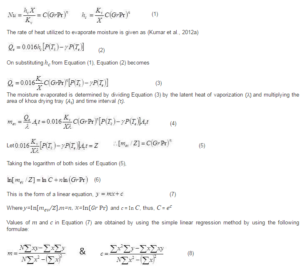

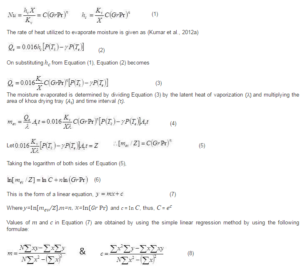

The convective heat transfer coefficient for evaporation under natural convection can be determined by using the following relations (Kumar et al., 2012a):

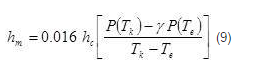

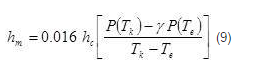

The experimental data given in Tables 1-3 for Tk, Te, γ, and mev were used to determine the values of y and  for different time intervals. Then the constant C and exponent n were obtained from the above equations for natural convection greenhouse drying mode. The experimental constants (C & n) were considered further for evaluating the values of convective heat transfer coefficients from Equation (1). The physical properties of humid air were determined by the expressions given in Appendix-A. The mass transfer coefficient (hm) were calculated from Equation (9) as given below (Kumar et al., 2012b):

for different time intervals. Then the constant C and exponent n were obtained from the above equations for natural convection greenhouse drying mode. The experimental constants (C & n) were considered further for evaluating the values of convective heat transfer coefficients from Equation (1). The physical properties of humid air were determined by the expressions given in Appendix-A. The mass transfer coefficient (hm) were calculated from Equation (9) as given below (Kumar et al., 2012b):

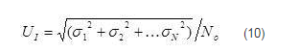

Experimental Error

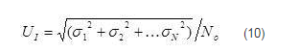

The experimental error was evaluated in terms of percent uncertainty (internal + external) for the mass of moisture evaporated. The following equation was used for internal uncertainty (Kumar 2013):

The percent internal uncertainty was determined by using the following expression:

% internal uncertainty = (UI/mean of the total observations) ×100 (11)

For external uncertainty, the least counts of all the instruments used in measuring the observation data were considered.

Results and Discussion

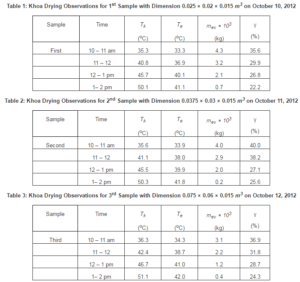

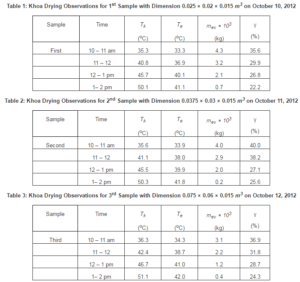

The experimental data recorded for khoa drying under natural convection greenhouse mode for khoa pieces with dimensions 0.025 × 0.02 × 0.015 m3, 0.0375 × 0.03 × 0.015 m3, and 0.075 × 0.06 × 0.015 are presented respectively in Tables 1, 2, and 3 given in Appendix-II.

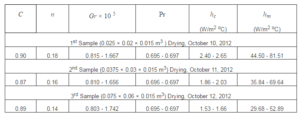

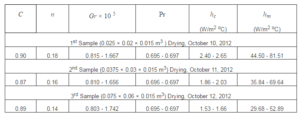

The data given in Tables 1-3 (Appendix-II) were used to determine the values of the constant C and exponent n in the Nusselt expression by simple linear regression analysis. Then the values of these constants were considered further for determining the values of the convective heat transfer coefficient by Equation (1). After determining the convective heat transfer coefficients, the mass transfer coefficients were evaluated from Equation (9). The evaluated values of experimental constants (C & n), the convective heat transfer coefficients (hc), and the mass transfer coefficients (hm) during drying all the khoa samples inside the greenhouse under natural convection mode are summarized in Table 4. The range of Grashof number and Prandtl number has also been given. The product of Grashof and Prandtl numbers has been observed as

Gr Pr ≤ 107, which indicates that the entire khoa drying falls within a laminar flow (Kumar et al., 2011b).

Table 4: Results of Evaluated Parameters and the Convective Heat and Mass Transfer Coefficients for Khoa Pieces

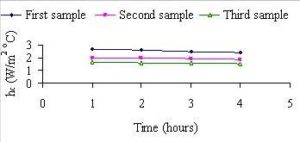

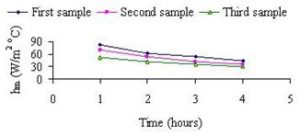

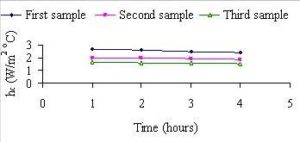

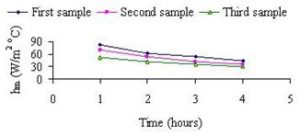

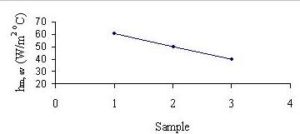

It has been observed from Table 4 that the values of convective heat and mass transfer coefficients are more for the khoa piece of dimension 0.025 × 0.02 × 0.015 m3. The convective heat and mass transfer coefficients decrease with the increase in size of the khoa pieces which is due to decrease in removal of moisture contents. The hourly variations in the convective heat and mass transfer coefficients for each sample of the given dimensions are illustrated in Figures 3 and 4 respectively.

Fig. 3: Variations in Convective Heat Transfer Coefficients versus Time

Fig. 4: Variations in Mass Transfer Coefficients versus Time

From Figures 3 & 4 it can be seen that the convective heat and mass transfer coefficients decrease with the progression of drying time interval for each sample of khoa. This is because of decrease in moisture removal with the increase in drying time interval for a particular day.

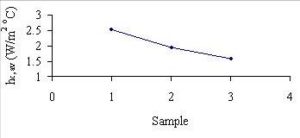

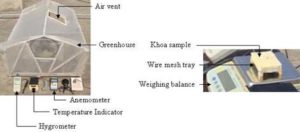

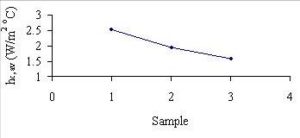

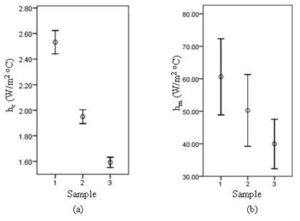

In order to make a comparison, the average values of convective heat and mass transfer coefficients have also been calculated for each dimensions of the khoa sample. The average values of convective heat transfer coefficients are found 2.53 W/m2 oC, 1.95 W/m2 oC, and 1.59 W/m2 oC for the khoa pieces of size 0.025 × 0.02 × 0.015 m3, 0.0375 × 0.03 × 0.015 m3, and 0.075 × 0.06 × 0.015 m3 respectively. The average value of convective heat transfer coefficients is observed to increase by 59.12% by decreasing the khoa sample size from 0.075 × 0.06 × 0.015 m3 to 0.025 × 0.02 × 0.015 m3. This could be due to increase in exposure of khoa surface area to solar radiations which causes increased moisture removal rate. The average value of the convective heat transfer coefficients has been plotted in Figure 5.

Fig. 5: Average Value of the Convective Heat Transfer Coefficients for Each Sample

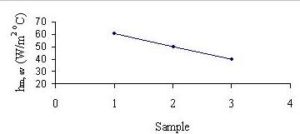

The average values of mass transfer coefficients are found 60.6 W/m2 oC, 50.25 W/m2 oC, and 39.95 W/m2 oC for the khoa pieces of size 0.025 × 0.02 × 0.015 m3, 0.0375 × 0.03 × 0.015 m3, and 0.075 × 0.06 × 0.015 m3 respectively. The average value of mass transfer coefficients is observed to increase by 51.69% by decreasing the khoa sample size from 0.075 × 0.06 × 0.015 m3 to 0.025 × 0.02 × 0.015 m3. This could be due to increased moisture removal rate and thus the convective heat transfer coefficients values with the decrease in size of the given khoa samples. The average value of the mass transfer coefficients for all the khoa samples is illustrated in Figure 6.

Fig. 6: Average Value of the Mass Transfer Coefficients for Each Sample

The average value of percent uncertainty (internal + external) is evaluated as 33.54%. Thus the different values of the convective heat and mass transfer coefficients were found to be within the given range. To show the variability of convective heat and mass transfer coefficients values from its true value SPSS software (version 16.0) has been used which provided error bars with 95% confidence interval. Error bars for the convective heat and mass transfer coefficients are illustrated in Figure 7(a) and (b) respectively.

Fig. 7: Error Bars for the Convective Heat and Mass Transfer Coefficients

Conclusions

The effect of the size on the convective heat and mass transfer coefficients for khoa drying under natural convection greenhouse mode for a given mass has been determined. The convective heat and mass transfer coefficients are more for the pieces of dimension 0.025 × 0.02 × 0.015 m3. The convective heat and mass transfer coefficients decrease with the increase in size of the khoa pieces which could be due to decrease in removal of moisture contents. The average values of convective heat and mass transfer coefficients are found to increase from 1.59 W/m2 oC to 2.53 W/m2 oC and 39.95 W/m2 oC to 60.6 W/m2 oC respectively for decreasing the size of khoa pieces from 0.075 × 0.06 × 0.015 m3 to 0.025 × 0.02 × 0.015 m3. The convective heat and mass transfer coefficients are also observed to decrease with the progression of drying time interval during each day of drying. This is because of decrease in moisture removal with the increase in drying time interval. Thus from the present research work it is inferred that the size of khoa pieces plays a significant role in its drying. This research work would be highly useful in the design of an efficient greenhouse dryer for khoa drying to its optimum storage moisture level.

Nomenclature

At Area of wire mesh tray, m2

C Experimental constant

C v Specific heat of humid air, J/kg oC

g Acceleration due to gravity, m/s2

Gr Grashof number = β g X3 Ïv 2 ∆T / μv 2

hc Convective heat transfer coefficient, W/m2 oC

hc,av Average convective heat transfer coefficient, W/m2 oC

hm Mass transfer coefficient, W/m2 oC

hm,av Average mass transfer coefficient, W/m2 oC

Kv Thermal conductivity of humid air, W/m oC

m ev Mass evaporated, kg

n Experimental constant

N Number of observations in each set of tables

Number of sets

N u Nusselt number = hc X / Kv

Pr Prandtl number = μv C v / Kv

P(T ) Partial vapor pressure at temperature T, N/m2

Rate of heat utilized to evaporate moisture, J/m2 s

Tk Temperature of khoa surface, oC

Te Temperature just above the khoa surface, oC

t Time, s

∆T Effective temperature difference, oC

X Characteristic dimension, m

Greek Symbols

β Coefficient of volumetric expansion (K-1)

γ Relative humidity (%)

λ Latent heat of vaporization, J/kg

μv Dynamic viscosity of humid air, N s/m2

Ïv Density of humid air, kg/m3

σ Standard deviation

References

Chavan, K. D. & Kulkarni, M. B. (2006). “Solar Radiation- An Effective Approach for Khoa Preservation,” Journal of Dairying, Foods and Home Sciences, 25(3/4), Pp. 182-185.

Publisher – Google Scholar

Condori, M., Echazu, R. & Saravia, L. (2001). “Solar Drying of Sweet Pepper and Garlic Using the Tunnel Greenhouse Drier,” Renewable Energy, 22(4), Pp. 447-460.

Publisher – Google Scholar

Kumar, A. & Tiwari, G. N. (2006). “Effect of Shape and Size on Convective Mass Transfer Coefficient During Greenhouse Drying of Jaggery,” Journal of Food Engineering, 73, Pp.121-134.

Publisher – Google Scholar

Kumar, C. N., Kumaresan, G. & Saravanan, K. (1996). ‘Incidence of Moulds in Khoa,’ Indian Journal of Dairy Science,49, Pp. 462-464.

Kumar, M. (2013a). “Up-Gradation of Khoa Production and Preservation Technologies,” S-JPSET, 3(1), Pp. 1-6.

Publisher – Google Scholar

Kumar, M. (2013b). “Forced Convection Greenhouse Papad Drying: An Experimental Study,” Journal of Engineering Science and Technology, 8 (2), Pp. 191 — 207.

Publisher – Google Scholar

Kumar, M., Kasana, K. S., Kumar, S. & Prakash, O. (2011a). ‘Experimental Investigation on Convective Heat Transfer Coefficient for Khoa Drying,’ International Journal of Current Research, 3(8), Pp. 88-93.

Google Scholar

Kumar, M., Khatak, P., Sahdev, R. K. & Prakash, O. (2011b). “The Effect of Open Sun and Indoor Forced Convection on Heat Transfer Coefficients for the Drying of Papad,” Journal of Energy in Southern Africa, 22(2), Pp. 40-46.

Publisher – Google Scholar

Kumar, M., Kumar, S., Prakash, O. & Kasana, K. S. (2012b). “Evaporative Heat Transfer Coefficients during Sensible Heating of Milk,” S-JPSET, 3(1), Pp. 1-6.

Publisher – Google Scholar

Kumar, M., Prakash, O. & Kasana, K. S. (2012a). “Experimental Investigation on Natural Convective Heating of Milk,”Journal of Food Process Engineering, 35(5), Pp. 715-726.

Publisher – Google Scholar

Kumar, M., Prakash, O., Kasana, K. S. & Dabur, R. S. (2010). ‘Technological Advancement in Khoa Making,’ Indian Dairyman, 62(1), Pp. 64-70.

Google Scholar

Rajarajan, G., Kumar, C. N. & Elango, A., (2007). “Distribution Pattern of Moulds in Air and Khoa Samples Collected from Different Sections of Khoa Plants,” Indian Journal of Dairy Science, 60(2), Pp. 133-135.

Publisher – Google Scholar

Tiwari, G. N., Kumar, S. & Prakash, O. (2004). “Evaluation of Convective Mass Transfer Coefficient during Drying of Jaggery,” Journal of Food Engineering, 63, Pp. 219-227.

Publisher – Google Scholar

Appendix-I

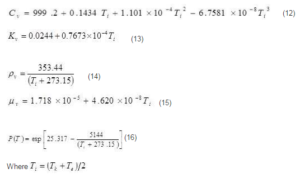

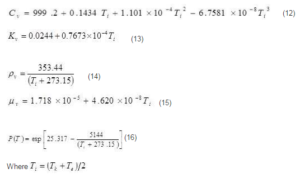

The following expressions were used for determining the values of the physical properties of humid air (Kumar et al., 2012a; Kumar 2013):

Appendix-II